When it comes to soldering, there are several methods available, each with its own set of advantages and applications. Two common soldering techniques that you might encounter are Hot Air Soldering and Traditional Soldering. In this article, we'll explore the differences between these methods, their respective benefits, and when each one is most suitable for your soldering projects.

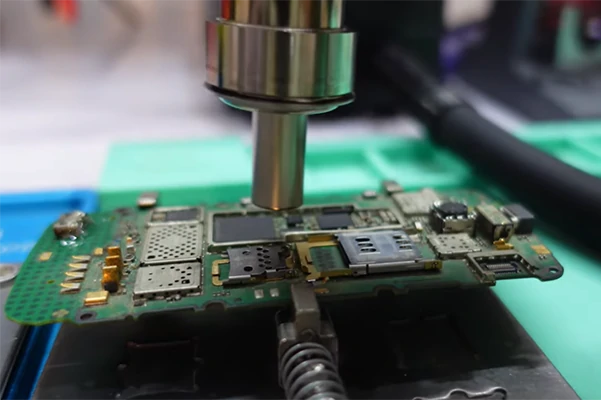

Hot Air Soldering, also known as SMD (Surface Mount Device) rework, is a soldering technique that uses heated air to melt solder paste or solder wire. This method is especially useful for soldering and desoldering surface mount components on circuit boards. The hot air is directed onto the targeted area, heating the solder and component leads until they reach the required temperature for bonding or removal.

Versatility: Hot Air Soldering is ideal for soldering delicate and heat-sensitive components that traditional soldering methods may not be suitable for.

Reflow Soldering: It allows for reflow soldering, making it easier to solder multiple components simultaneously on complex circuit boards.

Efficient Desoldering: Hot Air Soldering is an excellent choice for desoldering and reworking components without causing damage to the surrounding circuitry.

Reduced Risk of Damage: As the hot air targets specific areas, there is less risk of heat spreading to other components, reducing the chance of accidental damage.

Traditional Soldering, often referred to as through-hole soldering, is the classic method of soldering electronic components. In this technique, a soldering iron is used to heat the solder, creating a molten state that bonds the components and conductive pads on the circuit board.

Widely Used: Traditional Soldering is a widely practiced technique and has been the standard for many decades, making it familiar to most electronics enthusiasts.

Suitable for Through-Hole Components: It is particularly effective for soldering through-hole components on a printed circuit board (PCB).

Stability: When soldering larger and heavier components, traditional soldering can provide better stability and control.

Affordability: Soldering irons used in traditional soldering are generally more affordable than hot air soldering equipment.

The choice between Hot Air Soldering and Traditional Soldering depends on the specific requirements of your projects. Consider the following factors when making your decision:

Component Type: For surface mount components, Hot Air Soldering is usually the preferred method due to its precision and reduced risk of damage. For through-hole components, Traditional Soldering is often more suitable.

Project Complexity: If you're dealing with complex PCBs with densely populated components, Hot Air Soldering might be the better choice for reflow soldering and efficient rework.

Experience and Skill: Traditional Soldering is generally more approachable for beginners, while Hot Air Soldering may require more skill and practice to master.

Tools and Equipment: Consider the initial investment required for each method, as Hot Air Soldering typically requires a specific hot air station, while Traditional Soldering can be performed with a soldering iron.

One hot air station stands out among the top brands – the AiXun H310D. Let's explore what sets it apart from the competition:

- 3.5-inch IPS digital screen: Provides a clear and detailed display for precise control and monitoring during soldering tasks.

- OTA upgrade support: Stay up-to-date with the latest features and improvements for enhanced performance.

- Dual combination of segment desoldering and curve desoldering: Achieve high-precision desoldering results for both simple and complex components.

- Silent brushless air blower: Ensures a quiet working environment while delivering powerful and consistent airflow for efficient soldering.

- 1000W high-power heating core: Rapidly heats up to the desired temperature, reducing waiting time and increasing productivity.

- One key switch among three desoldering modes: Easily switch between segment desoldering, curve desoldering, and standard soldering modes for versatile usage.

In the battle of Hot Air Soldering vs. Traditional Soldering, both methods have their strengths and applications. Hot Air Soldering shines in the realm of surface mount component soldering and rework, offering precision and versatility. On the other hand, Traditional Soldering remains a reliable and widely-used technique for through-hole component soldering.

Ultimately, the decision between the two methods depends on the nature of your projects, your skill level, and the specific components you'll be working with. Whichever technique you choose, remember to prioritize safety and invest in quality soldering tools to ensure successful and reliable results in your electronic projects.

WhatsApp

WhatsApp